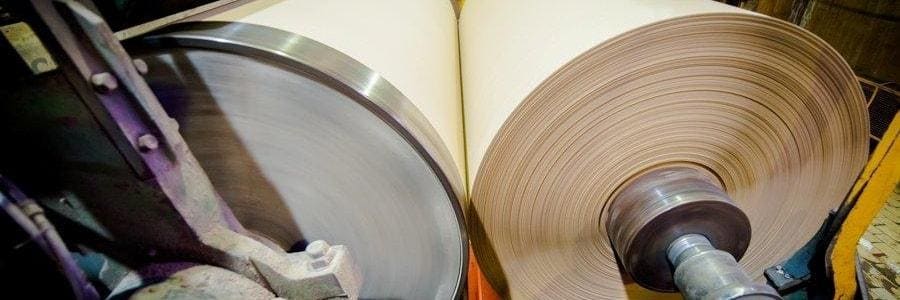

How is paper cores produced?

Technology for producing paper tubes

Paper tubes are manufactured from sleeved cardboard, using equipment called sleeving machines. These are electrically and pneumatically driven machines. An average bushing machine is made up of five assemblies: a forming unit, a cutter, an unwinder, a gluer and a conveyor. How do they work? The entire process takes place automatically. First, the first strip of tuleboard through the unwinder and the gluer (the first layer has no glue yet) goes under the forming spindle. There it is formed accordingly. Then the next strips (this time already with glue) are pulled. The cardboard strips go one under the other, adhesive surface inwards. The glued and shaped tube flows down the guide tube, where it is cut to the desired lengths. It then falls onto the conveyor and arrives on the receiving table.

Modern bushing machines

Modern bushing machines are electronically controlled and equipped with an operator panel. The machine operator can give the machine the desired operating parameters, such as inner diameter of the sleeve, strip width, distance and time of the drop valve, wall thickness, unwinder rotation, etc. These are relatively large machines, manufactured from steel and properly protected against corrosion. In the production of paper cores, it is not only the quality of the machine that is important, but also the quality of the coreboard used. It should be characterised by high strength parameters. The sleeve boards we offer are tested on: SCOTT BOND, thickness, BULK, moisture content, COBB 60, breakability. They are suitable for the production of sleeves, but also cardboard angles.